Manufacturing Facility

Since 1958, Eckel Manufacturing Co., Inc. is dedicated to ensure customers receive the highest quality oilfield products, services and training. Eckel manufactures over 40 models of hydraulic power tongs for the oil & gas industry and ships to more than 100 countries around the world along with international agents. Our modern manufacturing and heat treating facilities encompasses 140,663 square feet and is located in Odessa, Texas.

Eckel is the leading worldwide manufacturing of hydraulic power tongs for land and offshore drilling rigs and well servicing. Our broad offering of hydraulic power tongs in sizes 2-1/16 through 36 inch are capable to handle any drill pipe, casing, or tubing string. We have designed our tongs to offer the maximum safety while also maximizing productivity and reliability.

ISO 9001:2015 certified

ISO 9001:2015 is a set of quality standards established by the International Organization for Standardization (ISO), the largest developer of international standards for product and service quality. The ISO 9001:2015 standard measures a company's ability to understand and meet customer quality requirements, enhance customer satisfaction and achieve continual improvement.

Eckel's registered manufacturing operation ensures the utmost quality at our facilities at:

8035 North County Rd West, Odessa, TX 79764Manufacturing, Repair service, Domestic and International Sales, Design, Testing, and Distribution of Hydraulic Power Tongs and Hydraulic Power Units.

8101 North County Rd West, Odessa, TX 79764

Manufacturing, Repair service, Heat Treat Processing of Hydraulic Power Tongs and Hydraulic Power Units.

Standard: ISO 9001:2015

Certificate No: QSR-1182

Certified Since: 6/30/2021

Certification Date: 6/30/2024

Valid Until: 6/29/2027

Certificate Document: ISO 9001:2015 QSR-1182 ![]()

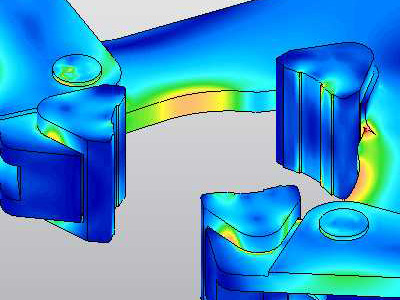

Engineering

From concept and design to manufacturing, our engineers play a crucial role in Eckel's success. Our engineers are hard at work at developing the next generation of hydraulic power tongs that push the design envelope. This has provided us opportunities to enhance our existing tong models as we develop new models for tomorrow tubulars requirements. Eckel utilizes the latest in Finite element analysis (FEA) software predict how our products react to real-world forces. Showing us whether a product will break, wear out, or work as designed.

Welding

Welders are in-house certified for mild steels and exotic steels that we employ in our equipment

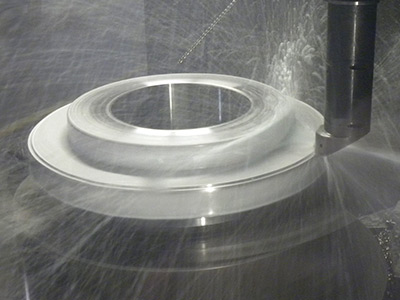

Machining

From rough machined to finished products, our CNC machining centers enables us to produce exceedingly tight tolerances�down to .0001 using the latest in CNC tooling.

- Turning

- Milling

- 4 & 5 Axis

- Drilling

- Plasma Cutting and Torch Cutting

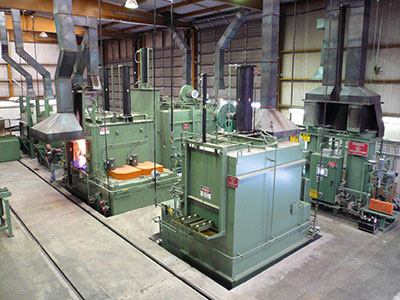

Heat Treating

We offer advanced in-house heat treating capabilities for insuring the highest possible quality standards throughout the thermal process. Key facilities offer accreditation for NADCAP steel and aluminum heat treat.

- 25 Years Heat Treating Experience

- Operates 24 Hours a Day

- Maximum Temperature 1800 degrees

- Quenching, Annealing

- Normalizing

- Gas Carburizing

Product Assembly

Our highly experienced assembly and hydraulic specialist assemble tongs and power units to their exacting specifications requirements. Hydraulic components are fitted to each tong to alleviate as much back pressure as possible.

Product Testing and Inpsection

Tongs and Hydraulic Power Units are performance tested for speed and torque. Performance Test Certificates are available for tongs and power units that certify the equipment met or exceeded our performance ratings. Performance tests are followed by inspection prior to shipment

- 20 point - Pre-Paint Tong Inspection

- 25 point - Final Tong Inspection

- 40 point - Power Unit Inspection