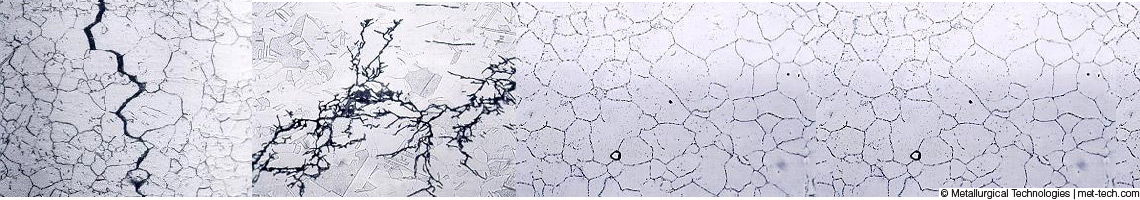

Hardened spots are susceptible to embrittlement causing microscopic fractures known as stress-corrosion cracking (SCC). SCC is cracking induced from the combined influences of tensile stress and corrosive environments that can eventually lead to tubular failure. Some design specifications for chrome tubing indicate acceptable penetration of less than 5% wall thickness while Eckel and numerous oil companies desire to alleviate all tubular penetration.

True Grit® Dies

Eckel Non-Marking True Grit® Dies - Have set a NEW industry standard for handling Corrosion Resistant Alloys (CRA) tubular goods. Eckel True Grit® Dies are used on chrome tubulars where reduced die penetration and die marking is greatly desired. Eckel's Coated True Grit® Dies utilize Tungsten Carbide grit which provides many more points of contact on the surface of the tubular than our Pyramid Fine Tooth dies. The Tungsten Carbide is a dense, metal like substance that does not flake or sheer off the face of the die. A head conversion kit for conversion of your head assembly to a head assembly for running chrome is required to obtain optimal performance from the True Grit® Dies. It is highly recommended to change the bushings in the roller after every job. For more information refer to our product page True Grit® Dies to help protect your CRA tubulars.