Our History

Eckel Manufacturing Company, Inc., was founded in 1958 by Emery L. Eckel. As operating costs-per-foot of drilling ballooned to staggering proportions, so likewise the need for fast, safe, efficient hydraulic power tongs. Emery saw it all coming, he had a particularly good vantage point. During the 1940s and 1950s, he operated tongs through out the U.S. He helped specify and purchase hydraulic tongs for others. Then Emery formed his own service organization, bought his own power tongs, trained his own casing crews, and kept the machinery running.The hydraulic power tongs of that era left a lot to be desired as they were prone to slip, wobble, and consequently damaged costly pipe. Some power trains were chain-driven, and these chains often snapped or snagged. Torque ratings were diminished by slipping clutches or "fading power" in their motors. While some models simply couldn't deliver the required torque, other power tongs packed enough power to "self destruct" a flimsy tong body if an over-zealous crew member applied full throttle.

Emery Eckel knew power tongs had to be better. In 1958, he set about improving them. He bought machine-tool time and rented unused corners of various shops around Odessa. He hired good machinist and welders when he could afford them, and learned to do their jobs when he couldn't. And one way or another, he produced tongs--new tongs with new ideas. Deficiencies in his tongs were ironed out, and soon Emery's casing tongs were in demand. As more profits came in, Emery reinvested the profits into production facilities. These new hydraulic tongs evolved into a prototype that embodies most the advantages still found in today's Eckel tongs. Other casing crews began asking for these different tongs, and Eckel produced them.

Terry L. Eckel, president of Eckel since 1987, has actively lead company operations and direction. Mr. Eckel has been very instrumental in the expansion the tong line offered. On October 31, 2011 Emery Eckel retired and his son Terry L. Eckel, CEO & Prisdent took ownership of the business and has continued to grow the company with the expansion of additional manufacturing capacity. Since 1958, the plant has doubled and redoubled in size several times. "Anywhere in the world" aptly describes the market for Eckel tongs today.

Eckel Timeline

60th Anniversary

2018 marks the 60th anniversary for Eckel. We are the oldest continuous leading manufacturer of world-class hydraulic power tongs and trusted for reliability, safety and high performance.

9-7/8 HS-55

Eckel 9-7/8 HS-55 Tubing / Casing providing high torque and high continuous rotational torque that you can trust within a compact operational footprint featuring SPACE SAVER™ technology.

9-7/8 HS HT-75

Providing a maximum torque of 75,000 ft-lbs (101686 Nm) and 50,000 ft-lbs (67790.9 Nm) continuous rotational torque; well suited for today's high torque premium casing connections.

25 HS-60, HS-80, HS-125

The Eckel Model 25 Hydra-Shift® HS-85 features a two-speed motor with two-speed gear train, producing 60,000, 80,000 and 125,000 ft-lb of torque respectively in low-low, at 2,500 psi. This tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches.

25 HS HT-200

The Eckel Model 25 Hydra-Shift® HT-200 Tri-Grip®introduced features a two-speed motor with two-speed gear train, producing 200,000 ft-lb of torque respectively in low-low, at 2,500 psi. This tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches - featuring a three head Tri-Grip®biting system design which like the Tri-Grip®New Revised Version Backup encompasses the tubular to apply an evenly distributed gripping force. The additional head in the tong reduces the risk of radial deformation, die penetration, marking, and wear of the tubular by 1/3 at extreme torques...

7.25 HS HT-80 Drillpipe/Casing Tong

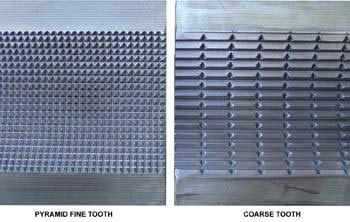

The new 7.25 HS HT-80 for Drill Pipe and High Torque Casing Tong takes on the toughest job with make-up and break-out of drill pipe, drill collars and high torque casing with a maximum torque of 80,000 ft-lbs. The 7.25 HS HT-80 is available with a two-speed Hydra-Shift® motor coupled with a two-speed gear train providing (4) torque levels and (4) RPM speeds. The variable speeds can slowly or quickly spin tubulars 2-3/8 through 7 1/4 inch as necessary. Having exceptional gripping capabilities with rig dies for drill pipe or wrap-around dies that securely encompass the tubular limit potential for damage. The 7.25 HS HT-80 is also available with either Eckel Pyramid Fine Tooth dies or True-Grit dies. The 7.25 HS HT-80 is another of our tongs models that exceeds the competition in its class.

5 1/2 UHT Model D

New Revised Version

Extremely popular among the most successful of pipe handlers, the Model 5 1/2 UHT combines high torque (up to 25,000 ft-lbs) with a wide capacity range. Ideal for handling tubing, casing and small drill pipe. Options include manual backup or Tri-Grip®backups.

3500 DTT Hydra-Shift® Model 5

New Revised Version

Wedge Drive Tri-Grip®Backup Intorduced

New Product - Initial Release

The WD Tri-Grip®Backup is a high performance no compromise backup that is suitable for make-up and break-out of the most resilient connections. The WD Tri-Grip®Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. A constant radial load is applied when a single wedge drive to actuate the front two pivot heads with a third stationary head providing a reactionary force to provide a superior gripping performance. Wedge Drive Tri-Grip®Backup has exceptional gripping capabilities with Rig Dies when running drill pipe or optional Eckel Wrap-Around True-Grit dies or Pyramid Fine Tooth dies for making up other types of tubulars.

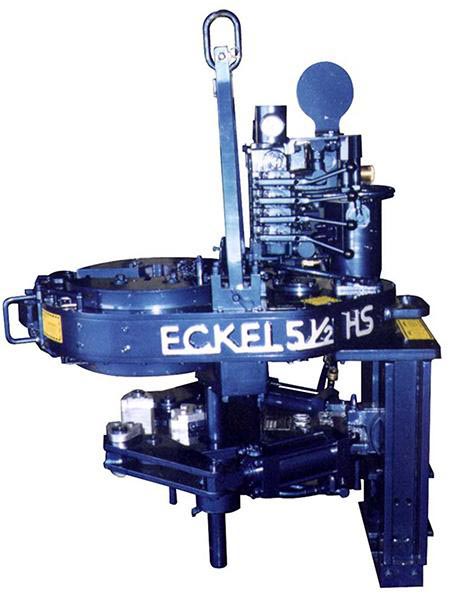

5 1/2 HS VS Model C

New Revised Version

4 1/2 Hydra-Shift® Model D

New Revised Version

The 4 1/2 Hydra-Shift® is packed with all the features you've come to expect from Eckel: patented cam biting system, quick-change sliding heads, self-aligning open throat. Options include both torque gauge and manual backup or cam-type hydraulic backup. The unit is also available with front or side controls, standard chain bridle suspension, or with its own built-in suspension arm.

20 Hydra-Shift® UHT

New Product - Initial Release

When applications demand the combination of size and high torque output up to 120,000 ft-lb, the Eckel Model 20 Hydra-Shift® UHT handles pipe from 7 inches to 20 inches. By utilizing a two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/rpm's to work with during make-up or break-out.

14 Hydra-Shift® Model C

New Revised Version

The Eckel Model 14 Hydra-Shift® handles pipe from 4 inches to 14 inches and incoporates the Hydra-Shift® technology which provides smoother operating environment and a wider selection of torque/RPM's that are available to the operator. The 14 Hydra-Shift® is capable of delivering 35,000 ft-lb of torque in low-speed, low-gear. Also available with hydraulic Tri-Grip®backup.

30 Hydra-Shift

The Eckel Model 30 Hydra-Shift® features a two-speed motor with a two-speed gear train, producing 130,000 ft-lb of torque in low-low at 2,500 psi. Weight 9,000 pounds, this tong easily handles ultra heavy casing strings from 14 inches to 30 inches.

14 Hydra-Shift® Model B

New Revised Version

The Eckel Model 14 Hydra-Shift® handles pipe from 4 inches to 14 inches and incoporates the Hydra-Shift® technology which provides smoother operating environment and a wider selection of torque/RPM's that are available to the operator. The 14 Hydra-Shift® is capable of delivering 35,000 ft-lb of torque in low-speed, low-gear. Also available with hydraulic Tri-Grip®backup.

13 3/8 Standard Model D

New Revised Version

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

22 HS-80

For casing up to 22 inches, here's a tong that has strong torqueing ability and will handle pipe sizes down to 7 inch. The tong utilizes a two-speed motor and a two-speed gear train, allowing the operator to correctly adjust the tong for the optimum torque and RPM needed for the current application. Maximum torque for the 22 Hydra-Shift® is 80,000 ft-lb.

20" STD Model B

New Revised Version

For casing up to 20 inches, here's a tong that combines surprising speed with an ability to handle smaller sizes economically (as small as 7 inches). The 20 Standard reaches peak efficiency at just 38 horse power input, thus requiring no "souped-up" power unit. Available torque: 42,000 ft-lb.

14 UHT Model E

New Revised Version

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

7-5/8 HDS Series

New Product - Initial Release

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 HS HD provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

7-5/8 HD Series Model C

New Revised Version

5 1/2 Standard Model C

New Revised Version

4 1/2 Hydra-Shift® Model D

New Revised Version

4 1/2 Hydra-Shift® Model C

New Revised Version

7 5/8 HD Series Model C

New Product - Initial Release

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

25 Hydra-Shift® Series

New Product - Initial Release

The Eckel Model 25 Hydra-Shift® features a two-speed motor with two-speed gear train, producing 60,000 ft-lb of torque in low-low, at 2,500 psi. Weighing 6,290 pounds, this tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches.

9 5/8 Hydra-Shift® HD

New Product - Initial Release

A maximum torque up to 25,000 ft-lb and a small foot print design this tong meets your application requirements. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and rpm's to work with during make-up or breakout. The 9 5/8 Hydra-Shift® HD is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

5 1/2 UHT Model C

New Revised Version

Extremely popular among the most successful of pipe handlers, the Model 5 1/2 UHT combines high torque (up to 25,000 ft-lbs) with a wide capacity range. Ideal for handling tubing, casing and small drill pipe. Options include manual backup or Tri-Grip®backups.

4 1/2 UHT Model B

New Revised Version

4 1/2 UHT Model B

New Revised Version

21 Hydra-Shift® Model C

New Revised Version - Now Discontinued

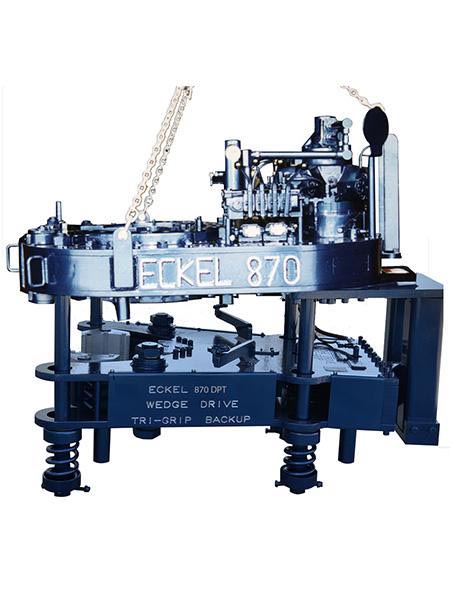

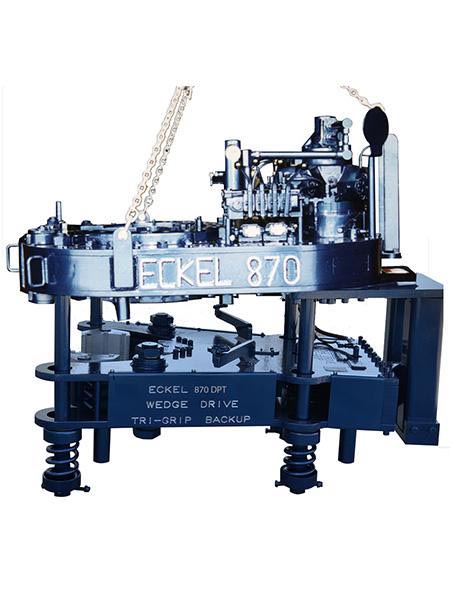

870 DPT Model B

New and imporoved version.

The Eckel 870 DPT combine power tong and Wedg Drive Tri-Grip®Backup, providing a single piece of equipment to replace several...one smooth continuous operation instead of numerous time-wasting steps at each connection...and a quick, safe means of tripping, replacing methods that endanger crew members and pipe string a like. For drill strings up to 8 inch collars, the model 870 offers over 75,000 ft-lb of torque for break-out and make-up operations, plus ample speed for spinning joints.

24 UHT

New Revised Version

The Eckel Model 24 UHT features a two-speed motor with single-speed gear train, producing 95,000 ft-lb of torque in low speed, 25,000 ft-lb in high, both at 2,500 psi. Weighing 8,000 pounds, this tong easily handles ultra-heavy casing strings from 13 3/8 inches to 24 inches.

10-3/4 Standard Model C

New Revised Version

Light, fast and exceptionally rugged, Eckel's Model 10 3/4 Standard is always in demand where rig floor space is at a minimum. For pipe sizes from 4 to 10 3/4 inches, it delivers a stout 20,000 ft-lb of available torque.

13 5/8 HD-30 and HD-35 Model D

New Revised Version

13 5/8 HD Model B HD30 and HD-35

New Revised Version

13 3/8 Standard Model C

New Revised Version

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

14 UHT Model D

New Revised Version

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

9-5/8 Hydra-Shift® NB Model B

New Revised Version

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM's to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

9-5/8 Hydra-Shift® NB

New Product - Initial Release

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM's to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

14 Hydra-Shift® HT

New Product - Initial Release

The 14 HS HT Tri-Grip®Tong is used for making up and break out casing and risers. Capable of handling tubulars from 4 in. to 14 in. (101.6 - 355.6 mm) in diameter with a maximum torque of 135,000 ft-lbs (183035.4) of torque capacity. A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. The tong features a three head - Tri-Grip®biting system design which like the Tri-Grip®Backup encompasses the tubular to apply an evenly distributed gripping force. The additional head in the tong reduces the risk of radial deformation, die penetration, marking, and wear of the tubular by 1/3 at extreme torques. The tong performs exceptional gripping capabilities with either Eckel True-Grit dies or Pyramid Fine Tooth dies.

10-3/4 Standard Model B

New Revised Version

Light, fast and exceptionally rugged, Eckel's Model 10 3/4 Standard is always in demand where rig floor space is at a minimum. For pipe sizes from 4 to 10 3/4 inches, it delivers a stout 20,000 ft-lb of available torque.

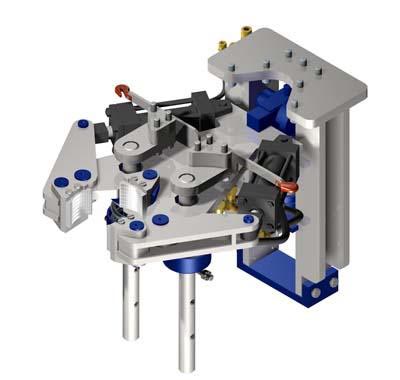

Top Drive

New Product - Initial Release

The Eckel Top Drive Casing Tong is a tool developed for use on hydraulic top drive rigs to provide a high quality connection while reducing tubular damage and providing a safer enviroment for crews. With an operating capacity of 4 1/2 inch through 10 5/8 inch, is connected to the output stem of the power swivel. After installation the tong becomes an integral part of the swivel, raising and lowering as a unit and transfering the power swivel's RPM and torque to the pipe/connection. A guide attached beneath the top drive tong simplifies alignment of the collar within the tong. Once the collar of the pipe is enclosed within the top drive tong, the tong will grip the collar by operating the power swivel. Torque and rotational speed are controlled through the operation of the power swivel. Reversal of the power swivel will cause the tong jaws to release. Tong jaws are spring loaded to retract away from the collar. Utilizing three gripping jaws and a patented Eckel Cam Biting System to grip the pipe collar. The same type of proven biting system found in the industry leading Eckel Power Tongs. These jaws are spaced evenly about the circumference of the collar to provide even distribution of the gripping forces

2 1/16 Hydra-Shift

The Oil & Gas Industry has needed a specialized power tong with an integral backup. This tong is sized small enough and has the right amount of controlable torque output. It is designed so as to properly grip small tubulars such as small macaroni type strings of tubing.

This tong incorporates Eckel's Hydra-Shift® technology for smooth tranfers of power and speed directly to the tubular. Special built in torque control valving allows the operator to pre-set the maximum desired torque for the connection. This tong also incorporates our new Radial Lock Door. If you are looking for a tong for this lighter type of word look no further.

13 3/8 Standard Model B

New Revised Version

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

7 5/8 Standard Model B

New Revised Version

5 1/2 Standard Model B

New Revised Version

3500 DTT Hydra-Shift® Model 5

New Revised Version

14 UHT Model C

New Revised Version

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

9-5/8 Hydra-Shift® NB Model B

New Revised Version

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM's to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

7-5/8 HD Series Model B

New Revised Version

21 Hydra-Shift® Model B

New Revised Version - Now Discontinued

5 1/2 UHT Model B

New Revised Version

Extremely popular among the most successful of pipe handlers, the Model 5 1/2 UHT combines high torque (up to 25,000 ft-lbs) with a wide capacity range. Ideal for handling tubing, casing and small drill pipe. Options include manual backup or Tri-Grip®backups.

14 UHT Model B

New Revised Version

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

7 5/8 HD Series Model B

New Revised Version

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

5 1/2 Hydra-Shift® Model B

New Revised Version

4-1/2 Hydra-Shift® Model B

New Revised Version

5 1/2 HS LS

New Product - Initial Release

Compact Size...Big Torque...if this is what you are looking for in a power tong, look no further. Our 5-1/2 Hydra-Shift® is sized smaller in width than our 5-1/2 Standard model. Like all of our newly developed tongs, the 5-1/2 incorporates the Hydra-Shift® technology, allowing the operator to shift from high speed to low speed without having to manually shift the tong. You will see many years of trouble free operation, not to mention the smoother hydraulic shifting. With two models to choose from, Eckel has the right 5-1/2 Hydra-Shift® for your needs. The 5-1/2 Hydra-Shift® LS with a two-speed motor and a single-speed gear train is the original 5-1/2 Hydra-Shift® which has gained wide acceptance in the industry. Slide heads with rig dies are available for handling drill pipe tool joints.

13 5/8 HD HD-30 and HD-35 Model B

New Revised Version

8 5/8 HS UHT

New Product - Initial Release

Special applications and tough requirements demanded that we respond with a new tong designed and built with today's pipe handling challenges in mind, the 8 5/8 Hydra-Shift® HT. By utilizing a two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/RPM's to work with during make-up or break-out. At the beginning of the job, the operator will choose a tong gear ratio that is most appropriate for the current tubular connection and shift the variable speed motor handle into high or low as required. This tong also offers sliding heads with wrap-around dies which provides an evenly applied pressure to the pipe and a greater pipe gripping coverage which in return reduce tubular damage. This tong not only offers the operator the speed options down to the slow speed parameter now demanded by the pipe manufactures and oil companies, it also has the option of speeds of 100 RPM's when required. Available torque: 40,000 ft-lb

7 5/8 HD Series

New Product - Initial Release

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

10 3/4 HD-25

New Product - Initial Release

When higher torque performance than 10 3/4 Standard is required, the Eckel 10 3/4 Heavy Duty provides the performance you need. Model 10 3/4 Heavy Duty is always in demand where rig floor space is at a minimum. For pipe sizes from 4 to 10 3/4 inches, it delivers a stout 25,000 ft-lb of available torque.

13 5/8 HD HD-30 and HD-35 Model B

New Revised Version

Tri-Grip®Backup Intorduced

New Product - Initial Release

Eckel Tri-Grip®an industry standard for reliable backup in make-up and break-out of tubular connections and optionally supplied with Eckel tongs. Eckel backups utilize hydraulic cylinders and a head arrangement that insures slip-free operation. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection. The Tri-Grip®uses two pivoting heads and one stationary while the cam backup uses two head to grip tubulars using a head and cam configuration that is similar to the method the tong grips tubulars.

4 1/2 CMT

New Product - Initial Release

The Eckel Closed Mouth Tongs uses three sliding heads with each head equipped with a wide angle wrap-around die. This provides a maximum gripping area of 342 degrees; on the pipe. The CMT's utilizes the Hydra-Shift® shifting technology which allows the operator to shift from high to low speed without stopping the tong. Reversing the pipe rotation is effortless and done simply by pulling the tong control in the opposite direction. There is no need to physically take out the jaws and turn them over as there is with other brands of closed head tongs. The CMT's also come with an optional backup that utilizes the same heads/dies as the tong.

4-1/2 UHT

New Product - Initial Release

The Model 4 1/2 UHT-13 is rugged, light weight tong capable of providing 8,500 ft-lb of torque at 2,500 PSI. The tong will handle pipe from 1.050 inches to 4 1/2 inches. A notable feature is the Eckel patented quick-change sliding head biting system that compensates for worn or under gauge pipe. Also available with an optional rod package for sizes 5/8 inch through 1-1/8 inches and your choice of manual type or hydraulic type backups.

17 Hydra-Shift

New Product - Initial Release

For casing up to 17 inches, here's a tong that combines speed and the ability to handle smaller sizes economically. If you are running 17 inch casing, give this tong a try. The 17 Hydra-Shift® features the two-speed motor and the two-speed gear train which allows for multiple selections of torque or RPM, not to mention the smoother operation of the tong.

3500 DTT Hydra-Shift® Model 4

New Revised Version

14 Hydra-Shift

New Product - Initial Release

The Eckel Model 14 Hydra-Shift® handles pipe from 4 inches to 14 inches and incoporates the Hydra-Shift® technology which provides smoother operating environment and a wider selection of torque/RPM's that are available to the operator. The 14 Hydra-Shift® is capable of delivering 35,000 ft-lb of torque in low-speed, low-gear. Also available with hydraulic Tri-Grip®backup.

21 Hydra-Shift

Initial Release - Now Discontinued

3500 DTT Hydra-Shift

New Product - Initial Release

The Eckel 3500 Hydra-Shift® DTT (Dual Tubing Tong) provides fast, easy running on dual strings of 3 1/2 inch or smaller tubing. It grabs from the side, or head-on. Go ahead and torque it up; this tong is Eckel tough. And speed shifts are no problem, thanks to a patented Hydra-Shift® concept that eliminates clutching. The Model 3500 DTT Hydra-Shift® is packed with all the features you've come to expect from Eckel: quick-change sliding heads, self-aligning open throat.

3.700 Ultralight

Initial Release - Now Discontinued

5 1/2 Hydra-Shift® VS

New Product - Initial Release

13 3/8 Standard

New Product - Initial Release

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

36 UHT

New Product - Initial Release

The big, capable Model 36 UHT easily produces 100,000 ft-lb of torque for makeup or break-out operations involving casing in sizes 16 inches through 36 inches. Weighing approximately 13,000 pounds, this casing tong is 81 inches wide and 135 inches in length. A two-speed motor delivers 16 RPM in high, 3 1/2 RPM in low range, both at 70 GPM.

870 DPT

New Product - Initial Release

The Eckel 870 DPT combine power tong and Wedg Drive Tri-Grip®Backup, providing a single piece of equipment to replace several...one smooth continuous operation instead of numerous time-wasting steps at each connection...and a quick, safe means of tripping, replacing methods that endanger crew members and pipe string a like. For drill strings up to 8 inch collars, the model 870 offers over 75,000 ft-lb of torque for break-out and make-up operations, plus ample speed for spinning joints.

8 5/8 Hydra-Shift

Initial Release - Now Discontinued

Eckel first introduction of Wrap-Around Dies

Eckel has been at the forefront of this developing technology with the development of larger wrap-around type dies for many of its tong models. Wrap-Around Dies are symmetrically spaced from each other at all times insuring an equally distributed load on the tubular.

4 1/2 Hydra-Shift

New Product - Initial Release

The 4 1/2 Hydra-Shift® is packed with all the features you've come to expect from Eckel: patented cam biting system, quick-change sliding heads, self-aligning open throat. Options include both torque gauge and manual backup or cam-type hydraulic backup. The unit is also available with front or side controls, standard chain bridle suspension, or with its own built-in suspension arm.

20 HT

Initial Release - Now Discontinued

5 1/2 Standard 5/8P

New improved version.

14 UHT

New Product - Initial Release

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

4 1/2 Standard

Initial Release - Now Discontinued

20 UHT

Initial Release - Now Discontinued

5 1/2 Standard

New Product - Initial Release

The Model 5 1/2 Standard is the first open-throat design in its size range to generate 12,000 ft-lb of available torque. Versatility is the name of the game here as this tong works well whether powered by a workover rig or a portable casing tong power unit. Options include manual backup or cam-type hydraulic backups.

13 3/8 SHT

Initial Release - Now Discontinued

5 1/2 UHT

New Product - Initial Release

Extremely popular among the most successful of pipe handlers, the Model 5 1/2 UHT combines high torque (up to 25,000 ft-lbs) with a wide capacity range. Ideal for handling tubing, casing and small drill pipe. Options include manual backup or Tri-Grip®backups.

13 3/8 UHT

Initial Release - Now Discontinued

10-3/4 Standard

New Product - Initial Release

Light, fast and exceptionally rugged, Eckel's Model 10 3/4 Standard is always in demand where rig floor space is at a minimum. For pipe sizes from 4 to 10 3/4 inches, it delivers a stout 20,000 ft-lb of available torque.

16" HT

Intial Release - Now Discontinued

8 5/8 UHT

Initial Release - Now Discontinued

3 1/2 Standard

Initial Rlease - Now Discontinued

Company Employee Photograph

Front row Emery Eckel in White and Terry Eckel in Black

7 5/8 Standard

When applications demand a wide range of sizes, the 7-5/8 Standard tong handles pipe sizes 2-1/16 inches all the way to 7-5/8. Its rugged design is based upon knowledge gained from the 5-1/2 model...combining an extremely compact, high torque concept with added versatility. Options include either manual backup or Tri-Grip®backup. Available torque: 15,000 ft-lb

13-3/8 Standard (Old Style)

Intial Release - Now Discontinued

16 STD

Intial Release - Now Discontinued

20 STD

New Product - Initial Release

For casing up to 20 inches, here's a tong that combines surprising speed with an ability to handle smaller sizes economically (as small as 7 inches). The 20 Standard reaches peak efficiency at just 38 horse power input, thus requiring no "souped-up" power unit. Available torque: 42,000 ft-lb.

11-1/4 Drill Pipe Tong

Intial Release - Now Discontinued

24 UHT

New Product - Initial Release

The Eckel Model 24 UHT features a two-speed motor with single-speed gear train, producing 95,000 ft-lb of torque in low speed, 25,000 ft-lb in high, both at 2,500 psi. Weighing 8,000 pounds, this tong easily handles ultra-heavy casing strings from 13 3/8 inches to 24 inches.

9-5/8 Standard (1st Tong)

Discontinued