Company Profile

Eckel engineers, designs, and manufactures world-class hydraulic power tongs for the oil and gas industry since 1958. From our main manufacturing facilities in Odessa, Texas, USA (ISO 9001:2015 certified) essentially every part is designed and manufactured. The facility encompasses 140,663 square feet and houses the latest in design tools and numerically controlled machines and heat treating ovens.

Overview

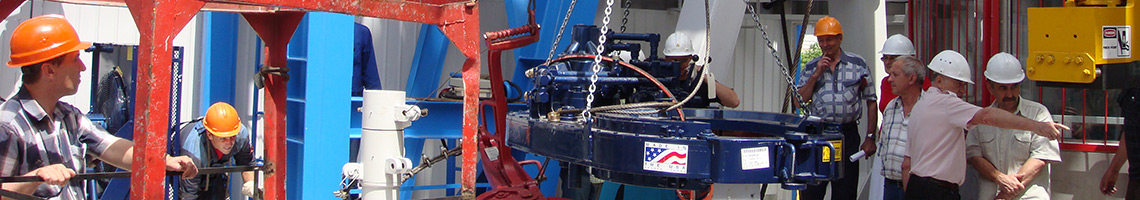

Established in 1958, Eckel is globally recognized as the leading manufacturer of hydraulic power tongs and hydraulic power units for the world's oil and gas industries. We offer a full line of hydraulically operated drill pipe tongs, casing tongs, tubing tongs, hydraulic backups, hydraulic power units, and tong positioning equipment. Eckel delivers a comprehensive range of tongs from 2-1/16 through 36 in. for the most demanding onshore and offshore environments. Eckel Tri-Grip®backup is an industry standard for reliable make-up and break-out of tubular connections. Eckel's cutting-edge designs, quality, and rugged durability have won us a world-wide reputation of a first-class product that insures years of trouble free service.

From our main manufacturing facilities in Odessa, Texas, USA (ISO 9001:2015 certified) essentially every part is designed and manufactured. The facility encompasses 140,663 square feet and houses the latest in design tools and numerically controlled machines and heat treating ovens.

Offerings

We offer a full range of high quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion and well servicing activities. Our tongs have been engineered for the high operational torques today's that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards.

- Improved crew efficiency such as our easy to open and close Radial Lock Door and our Hydra-Shift® speed shifting for speeding up turnaround time between connections.

- Integrated safety door interlock, patented cam biting, quick change slide heads

- Sliding heads with wrap-around dies are considered the best choice for thinner wall tubulars where point loading is a concern. The wrap-around dies are symmetrically spaced at all times insuring an equally distributed load on the tubular. A larger gripping surface allows more teeth to come in contact with the tubular.

- Our proprietary True Grit® have set NEW industry standards in handling Corrosion Resistant Allows (CRA) tubular goods. True Grit® are used on chrome tubulars where reduced die penetration and die marking is desired. TRUE GRIT® dies are long lasting 3 times longer than competing technologies and perform better than any steel tooth die when running (SUPER or HYPER) Chrome. Tubular penetration of the True Grit® is less than half of API allowable surface defect area.

- Our renowned free floating Tri-Grip®hydraulic backup provides unparalleled backup performance and is one of the industry's closest tong mounting backups that minimize pipe bending. The backup utilizes three biting surfaces to insure a secure grip on the tubular to prevent tubular rotation.

- Our remotely operated tongs provides a mean to control the tong for make-up and break-out operations. The tong is based upon the standard tong and backup configuration with the exception of hydraulic cylinders on the unit for remote control of the operations of the tong and backup. The functions include the tong door, backing pin, mechanical gear shift, power tong rotation, motor speed and backup gripping. Totally hydraulic with no electrical or electronic devices.

- We offer torque turn control systems that monitor torque turn values when making up tubular connection. Any flaws in the make-up process are readily shown.

- Eckel's standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are widely recognized for dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet "nonstandard" requirements for space, fluid flow, auxiliary power, and portability. Diesel driven units are optionally supplied with automatic shutdown systems to prevent engine run away when explosive gases are present. Additional shut downs include engine oil temperature, oil pressure, and fan belt breakage. All controls are either air, mechanical or electrical.

Eckel Manufacturing is committed to maintaining its position as an industry leader of the manufacturing of precision engineered specialty oil field equipment. It is our policy to provide our products at the highest quality that meets our customer's requirements and demands.

Eckel has a long standing commitment to:

- Assure 100% customer satisfaction.

- Produce the highest quality equipment in the industry.

- Provide a safe and efficient work environment for our employee's.

Our trained specialists are on hand in all areas of Russia for technical support during the commissioning of new equipment and when technical issues arise with running and handling of our products.