Wrap-Around Dies

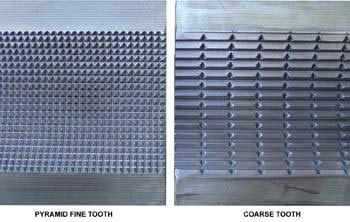

Wrap-Around Dies (Pyramid Fine Tooth and Carse Tooth)

Tong dies have come a long way since tongs became commonplace in the oilfields. Eckel has been at the forefront of this developing technology with the development of larger wrap-around type dies for many of its tong models. We offer coarse tooth design and fine tooth design depending on the application.

Wrap-Around Dies are considered the best choice for thinner wall tubulars where point loading is a concern. Wrap-Around Dies are symmetrically spaced from each other at all times insuring an equally distributed load on the tubular. Having a larger gripping surface area allows more teeth to come in contact with the tubular. Wrap-Around Dies come in any size to match tubing and casing tubulars and API coupling diameters. Wrap-Around dies are available with the following surface areas:

- Coarse Tooth Dies: Used on higher torque applications on carbon steel, hard band drill strings and drill collars.

- Pyramid Fine Tooth Dies: Used for slightly lower torque applications with chrome and fi berglass tubulars.

- Coated True Grit® Dies: Used on chrome and fiberglass tubulars where reduced die penetration and die marking is greatly. For more information see the True Grit® Dies section.

Eckel offers contour type dies for tubing sizes on many of our tongs which use pivot heads. In addition to our contour dies, we provide A and S series wrap-around dies for our 13-3/8 and 20 Standard casing tongs, providing a larger gripping area and reducing pipe damage. Rig type dies are used extensively for 4-inches and above. Sliding heads with rig dies is the best choice when running drill pipe connections.

Based in United States

Local time:

Date:

Sales Question or Technical Support?

Eckel Sales Representative

8035 North County Road WestOdessa, TX 79707

Ph: +1(432) 362-4336

Fax: +1(432) 362 1827

sales@eckel.com

Sliding Head Biting System

The Eckel Sliding head biting system utilizes our wide angle wrap-around type dies and is considered the best choice of power tong biting systems for use on small tubular. The biting surface of each wrap-around dies is symmetrically spaced 180-degress apart from each other at all times. This biting system provides a larger range of tubular coverage and allows for more die teeth to come in contact with the tubular while preventing it from moving off center and insuring an equally distributed load on the tubular connection.